H1HV, H2HV, H3HV, H4HV series Parallel Shaft Helical Gearbox

Technical Parameters:

| Available Models | H1HV03~H1HV19, H2HV4~H2HV26, H3HV5~H3HV26, H4HV7~H4HV26 |

| Съотношение | 1.25~450 |

| Входяща мощност | 5.5~4400 kW |

| Max torque | 2.9~900 kN.m |

ОПИСАНИЕ

H series parallel shaft helical gearbox is designed based on module with parallel shaft. The transmission torque distribution curve is excellent, suitable for heavy load conditions. It adopts advanced grinding technology and shape modification technology, which has high bearing capacity, reliable operation and low noise. The box body is made of high-quality casting to improve the mechanical strength and seismic performance of the reducer. Numerous mounting options are available.

ХАРАКТЕРИСТИКИ

- Adopt optimized modular design.

- Parallel shaft output form.

- The transmission torque distribution curve is excellent, suitable for heavy load conditions.

- Той използва усъвършенствана технология за смилане и технология за модификация на формата, която има висока носеща способност, надеждна работа и нисък шум.

- The box body is made of high-quality casting to improve the mechanical strength and seismic performance of the reducer.

- Numerous mounting options are available.

Продуктова форма

- Transmission Stage: single stage, 2 stage, 3 stage, 4 stage.

- Mounting: Horizontal mounted, Vertical mounted

- Parallel Output: Solid shaft, Hollow shaft ( flat key, shrink disk, involute spline), Splined solid shaft, flanged shaft

- Configuration options: With auxiliary tank, with oil pump, with cooling fan, with backstop, with hydraulic coupling, with gear unit swing-base

Технически данни

- Size: H3HV12-50-A, H1HV03~H1HV19, H2HV4~H2HV26, H3HV5~H3HV26, H4HV7~H4HV26

- Technical Data(kN·m): 2.9~900

- Gear Ratio: 1.25~450

- Input Power(kW):5.5~4400

Available Models

| Transmission stage | Съотношение(i) | Models |

| H1 | 1.25 – 5.6 | H1HV3, H1HV5, H1HV7, H1HV11, H1HV13, H1HV15, H1HV17, H1HV19 |

| H2 | 6.3 – 28 | H2HV4, H2HV5, H2HV6, H2HV7, H2HV8, H2HV9, H2HV10, H2HV11, H2HV12, H2HV13, H2HV14, H2HV15, H2HV16, H2HV17, H2HV18, H2HV19, H2HV20, H2HV21, H2HV22, H2HV23, H2HV24, H2HV25, H2HV26 |

| H3 | 25 – 112 |

H3HV5, H3HV6, H3HV7, H3HV8, H3HV9, H3HV10, H3HV11, H3HV12, H3HV13, H3HV14, H3HV15, H3HV16, H3HV17, H3HV18, H3HV19, H3HV20, H3HV21, H3HV22, H3HV23, H3HV24, H3HV25, H3HV26 |

| H4 | 90 – 450 | H4HV7, H4HV8, H4HV9, H4HV10, H4HV11, H4HV12, H4HV13, H4HV14, H4HV15, H4HV16, H4HV17, H4HV18, H4HV19, H4HV20, H4HV21, H4HV22, H4HV23, H4HV24, H4HV25, H4HV26 |

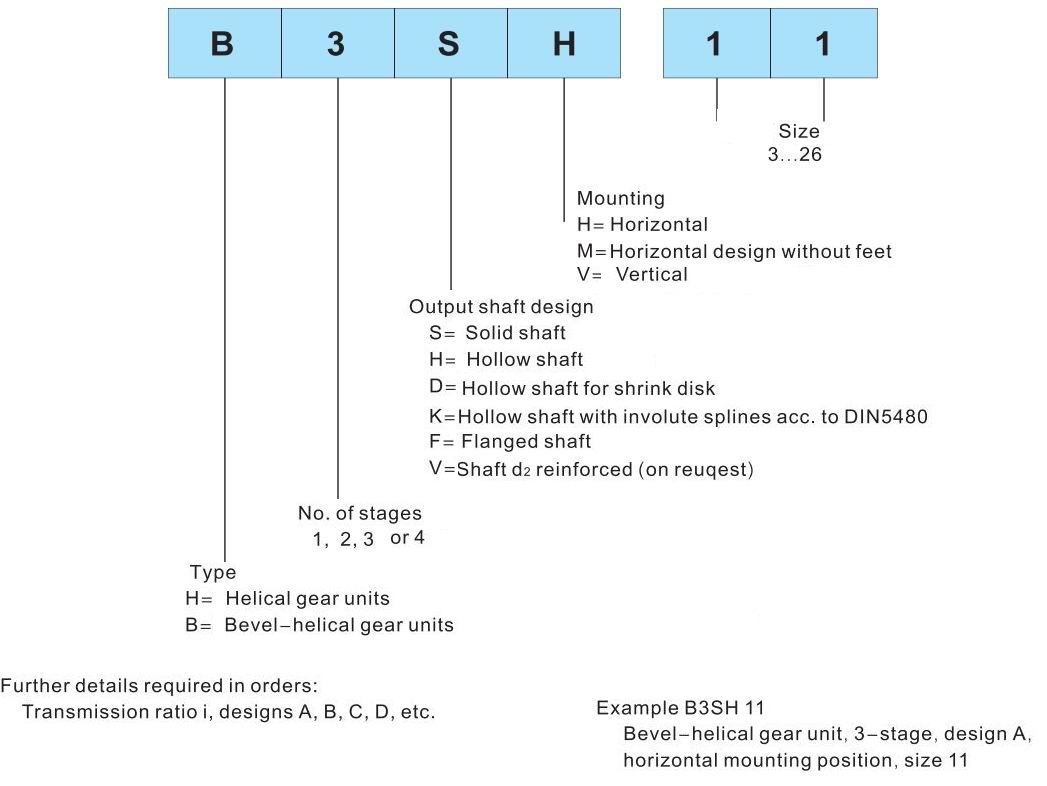

Тип и обозначение

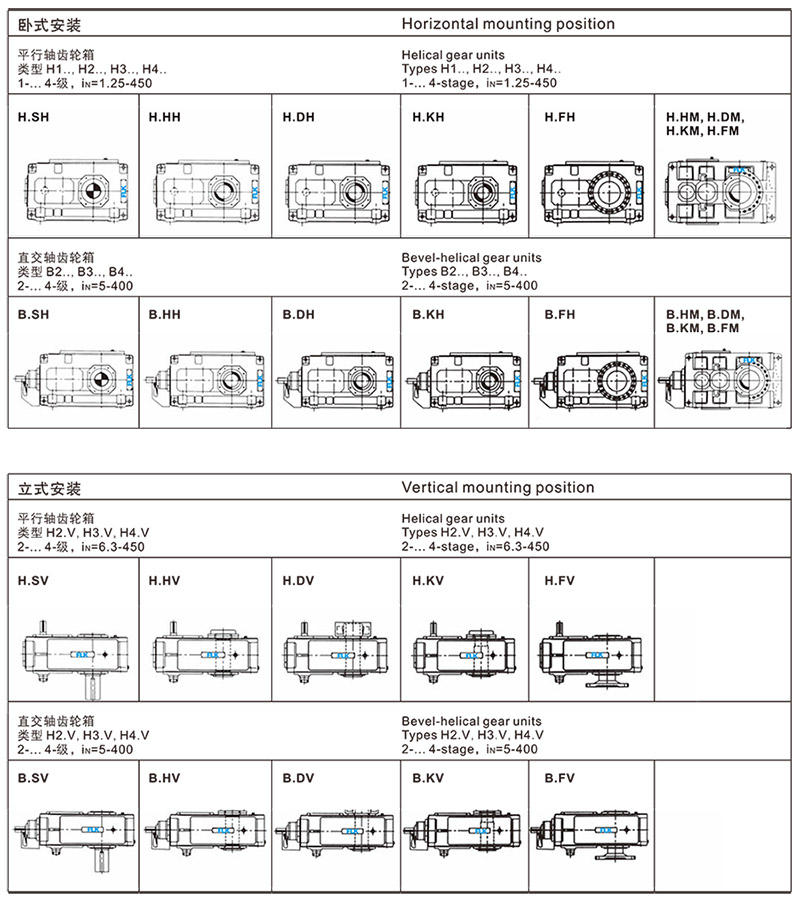

Монтажна позиция

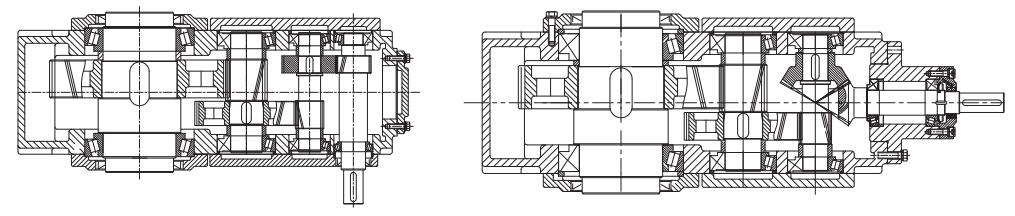

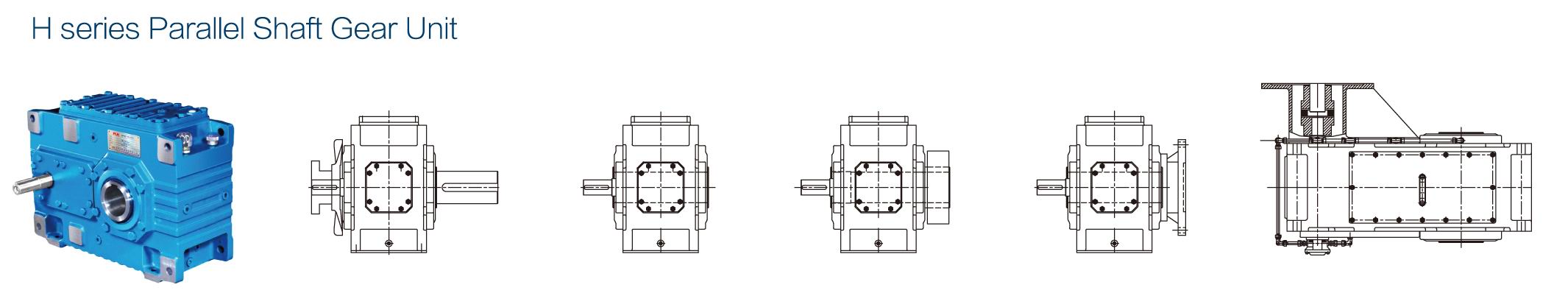

Чертеж на структурата

MODULAR DESIGN

PRODUCT PICTURES

H3HV12 Parallel Shaft Helical Gear Box

H3SH6 Parallel Shaft Helical Gearbox

H3SH12 Helical Reduction Gear Box

Приложение:

Parallel shaft helical industrial gearboxes се използват широко в леката промишленост, хранително-вкусовата промишленост, бирата и напитките, химическата промишленост, ескалаторите, оборудването за автоматично съхранение, строителството, машините, металургията на желязото и стоманата, производството на хартия, машините за дървени панели, производството на автомобили, машините за тютюневи изделия, опазване на водата, печат и опаковане, фармацевтични, текстилни, строителни материали, логистика, машини за фураж, опазване на околната среда и други области.