S series Worm Helical Gearbox with IEC Flange

| Model | S37, S47, S57, S67, S77, S87, S97, S67RF37, S77RF37, S87RF37, S97RF37 |

| 比率 | 6.8 ~ 288 |

| 入力電力 | 0.12 ~ 22 kW |

| Output torque | 11 ~ 4650 N.m |

説明

S series Worm Helical Gearbox is different from ordinary worm gearbox ,the input side adopts a pair of helical reducing to come true reducing rotary speed and reducing hot’s creating, meanwhile, it can gain larger transmission ratio. the structure are reasonable, can combine with R series inline helical gearbox, MB series variable speed gearbox, satisfy different clients’ using demands.

The design of helical worm gearbox is based on modular design. The helical worm gear reducer adopts a combination of helical gear and worm gear. So, it has higher efficiency and strength than single-stage aluminum worm gearbox. Because of the outstanding efficiency, the helical worm gear units can be used in every industrial sector and customized to meet individual torque and speed requirements. The gear ratios afforded by a single-stage helical-worm gear and the low noise level during running make the transmission device ideal for low-cost solutions in simple applications.

特徴

- 最適化された設計、モジュールの組み合わせを採用。

- Right angle output, with self-locking function under certain conditions, small vibration.

- 高度な研削技術と形状修正技術を採用しており、高い支持力、信頼性の高い動作、低騒音を備えています。

- シール性に優れ、幅広い作業条件に適します。

- 伝達効率が高く省エネです。

- コスト効率が高く、メンテナンスも簡単です。

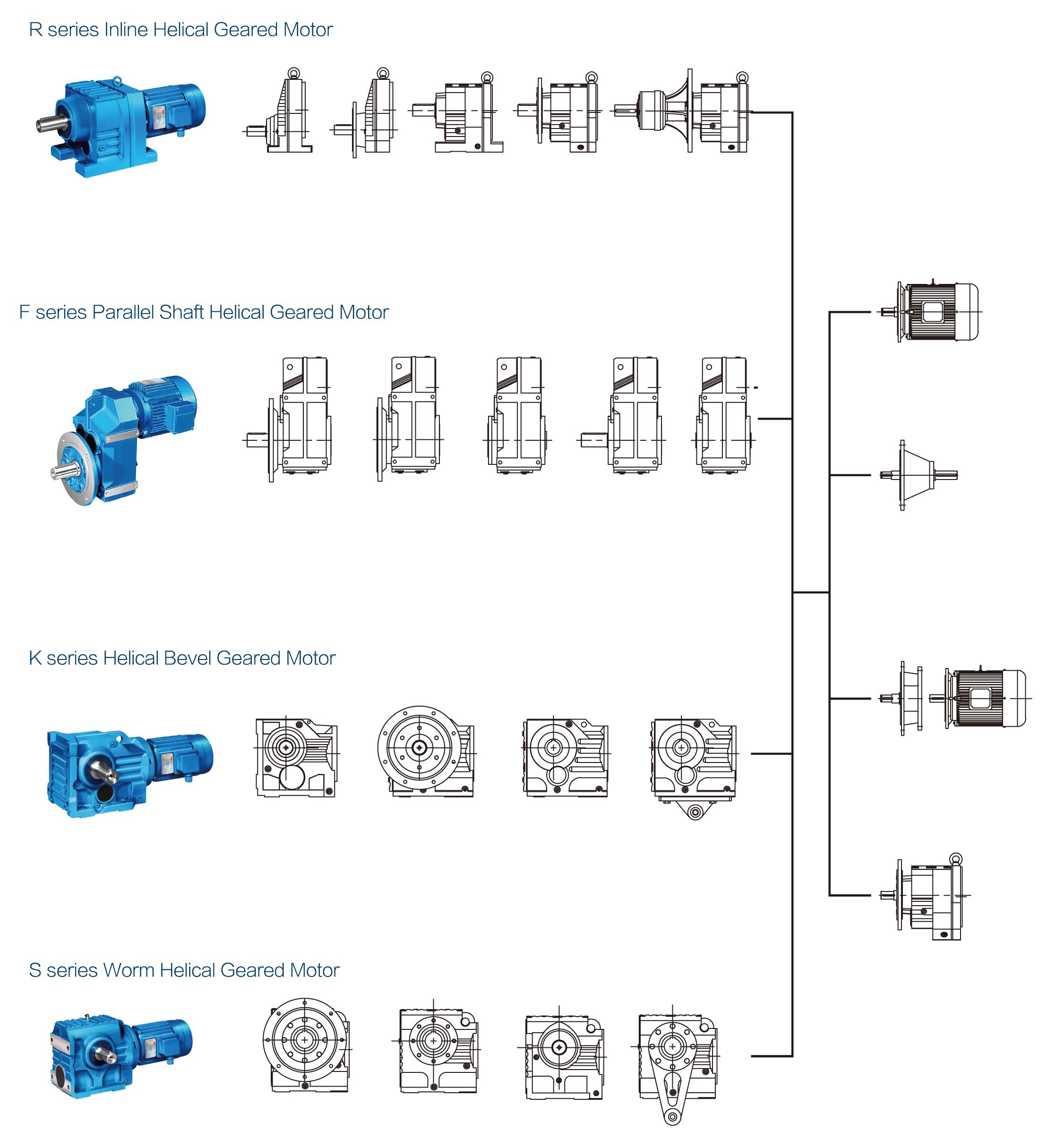

製品形態

- Transmission Stage: 2 stage.

- 組立形式:脚取付、フランジ取付、B14小フランジ取付、トルクアーム取付。

- ライトアングル出力:中実軸、中空軸(フラットキー、シュリンクディスク、インボリュートスプライン)、スプライン中実軸

技術データ

- Size: SF37~SF97

- Technical Data(N·m): 90~4000

- Gear Ratio: 6.8~286.4(imax:26688)

- Input Power(kW):0.12~22

Input Power Rating and Max Torque

|

サイズ |

S37 | S47 | S57 | S67 | S77 | S87 |

S97 |

|

構造 |

S SA SF SAF SAT SAZ |

||||||

|

入力電力定格 (kw) |

0.18-0.75 | 0.18-1.5 | 0.18-3 | 0.25- 5.5 | 0.55-7.5 | 0.75-15 |

1.5-22 |

|

比率 |

10.27-152 | 11.46-244.74 | 10.78-196.21 | 11.5-227.20 | 9.96-241.09 | 11.83-222 | 12.75-230.48 |

| 最大トルク(N・m) | 90 | 170 | 295 | 520 | 1270 | 2280 |

4000 |

AVAILABLE MODELS

|

バージョン

|

サイズ

|

|||||||

|

37

|

47

|

57

|

67

|

77

|

87

|

97

|

||

|

S..

|

Foot-mounted worm helical gear unit

|

S37

|

S47

|

S57

|

S67

|

S77

|

S87

|

S97

|

|

SF..

|

B5 Flange-mounted helical worm gearbox

|

SF37

|

SF47

|

SF57

|

SF67

|

SF77

|

SF87

|

SF97

|

|

SAF..

|

B5 Flange-mounted / Hollow shaft worm helical gearmotor

|

SAF37

|

SAF47

|

SAF57

|

SAF67

|

SAF77

|

SAF87

|

SAF97

|

|

SHF..

|

B5 Flange-mounted / Hollow shaft / Shrink disc worm helical reducer

|

SHF37

|

SHF47

|

SHF57

|

SHF67

|

SHF77

|

SHF87

|

SHF97

|

|

SA..

|

Hollow shaft helical worm speed reducer

|

SA37

|

SA47

|

SA57

|

SA67

|

SA77

|

SA87

|

SA97

|

|

SH..

|

Hollow shaft / Shrink disc worm helical gear unit

|

SH37

|

SH47

|

SH57

|

SH67

|

SH77

|

SH87

|

SH97

|

|

SAT..

|

Hollow shaft / Torque arm worm helical speed reducer

|

SAT37

|

SAT47

|

SAT57

|

SAT67

|

SAT77

|

SAT87

|

SAT97

|

|

SAZ..

|

B14 Flange-mounted / Hollow shaft worm helical gear reducer

|

SAZ37

|

SAZ47

|

SAZ57

|

SAZ67

|

SAZ77

|

SAZ87

|

SAZ97

|

|

SHZ..

|

B14 Flange-mounted / Hollow shaft / Shrink disc helical worm reducer

|

SHZ37

|

SHZ47

|

SHZ57

|

SHZ67

|

SHZ77

|

SHZ87

|

SHZ97

|

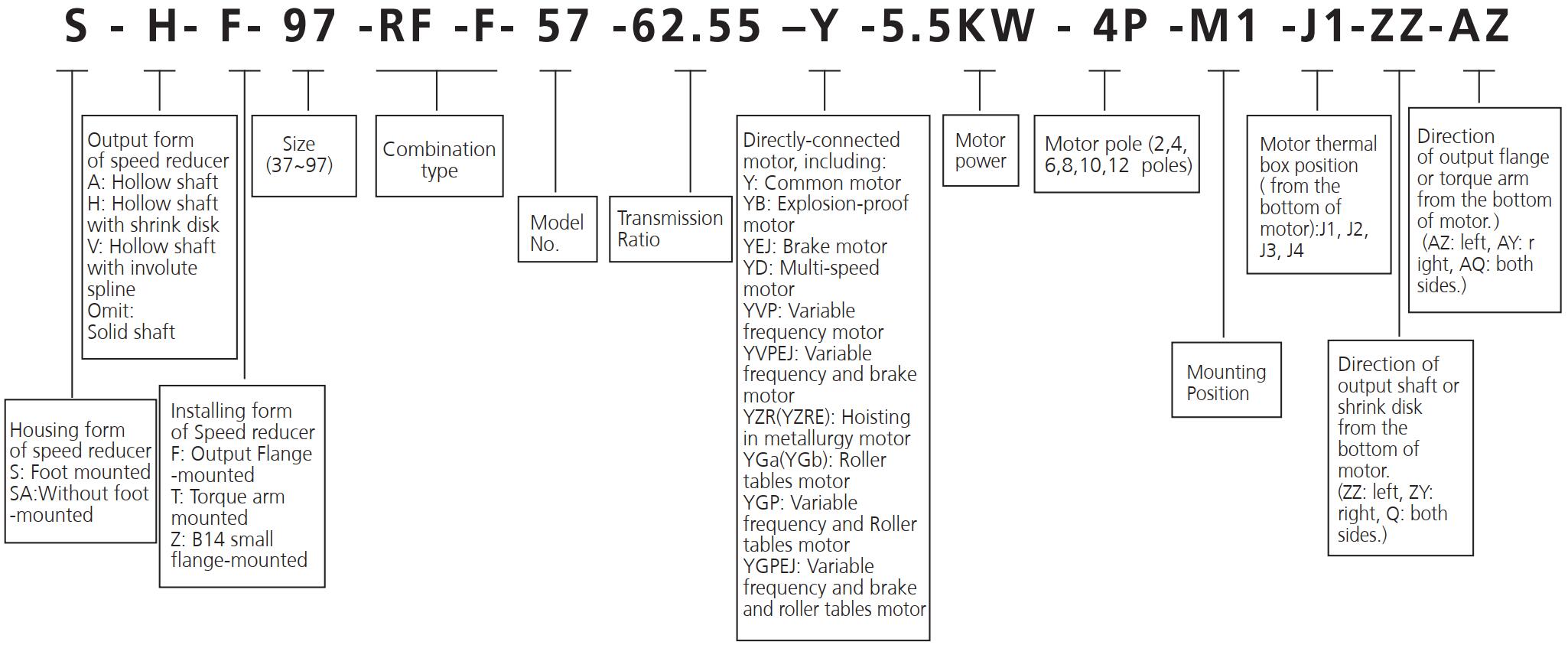

Type and Designation: (Worm Helical Gearmotor)

- モーター直結減速機: S–H–F–97–62.55–Y–5.5KW–4P–M1–J1–ZZ–ザ

- Directly-connected motor Speed reducer(Combination type): S–H–F–97–RF–F–57–62.55–Y–5.5KW–4P–M1–J1–ZZ–ザ

- With motor and input flange: S–H–F–97–62.55–AM132B5–Y–5.5KW–4P–M1–J1–ZZ–ザ

- Input flange-mounted, without motor: S–H–F–97–62.55–AM132B5–M1–J1–ZZ–ザ

- With input shaft: S–H–F–97–62.55–AD4–M1–ZZ–ザ

注記:

AM132B5:IECフランジの寸法(カタログをご参照ください)

AD4:インプットシャフト(AD1、AD2、AD3、AD4、AD5、AD6、AD7、AD8)

モーターコード:

※Y:標準三相モーター

※YB:防爆モーター

※YEJ:ブレーキモーター

※YD:多段速モーター

※YVP:可変周波数モーター

※YCT:電磁式速度調整モーター

*YR: クレーンおよび冶金モーター

※YVPEJ:可変周波数・ブレーキモーター

※YG:ローラーテーブルモーター

*YGPEJ: 可変周波数およびブレーキおよびローラーテーブルモーター

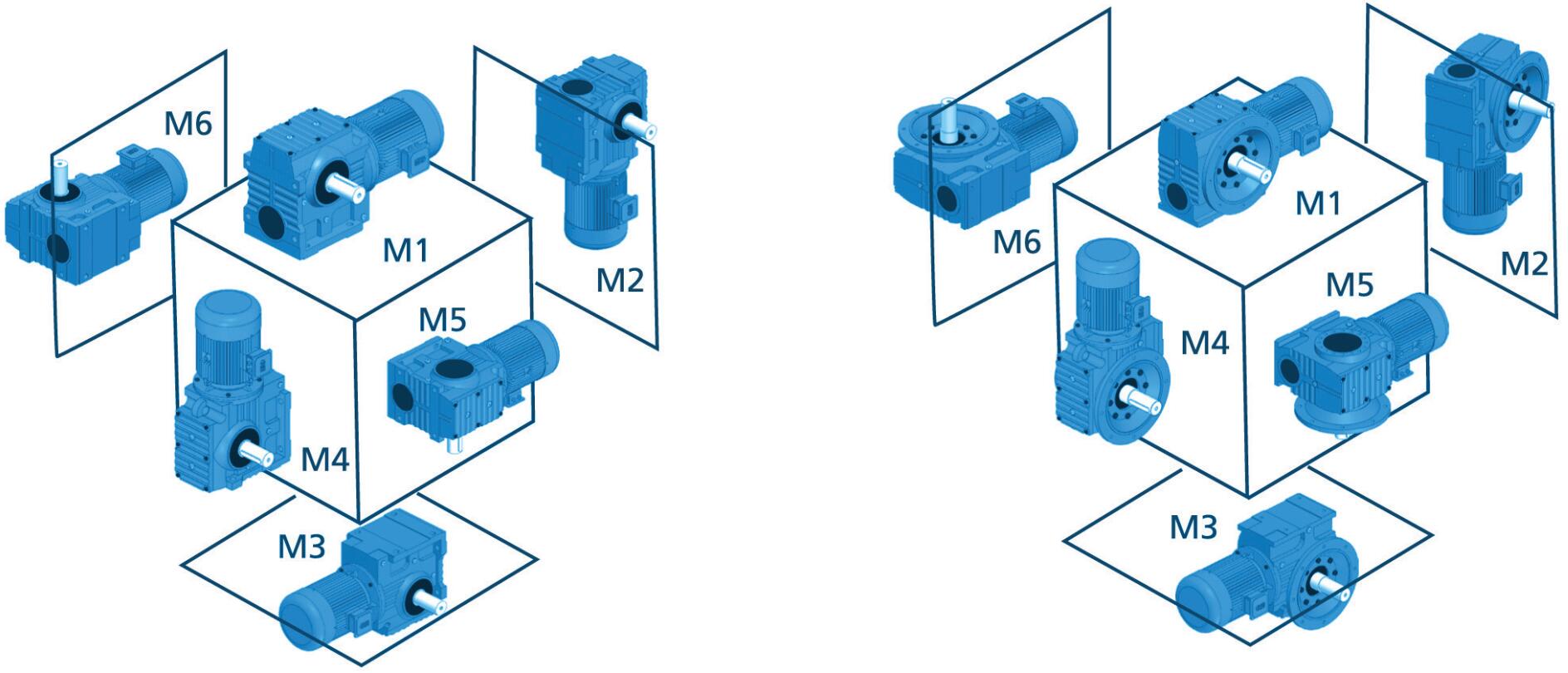

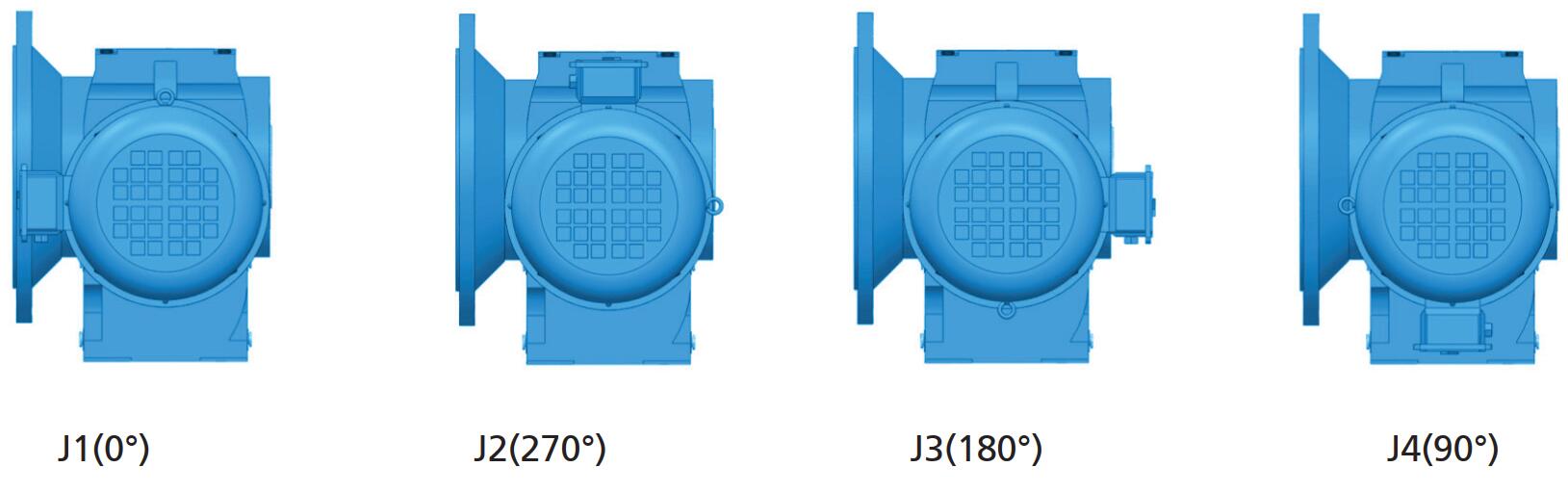

Mounting Position (Worm Helical Gearmotor)

モーター端子箱の位置

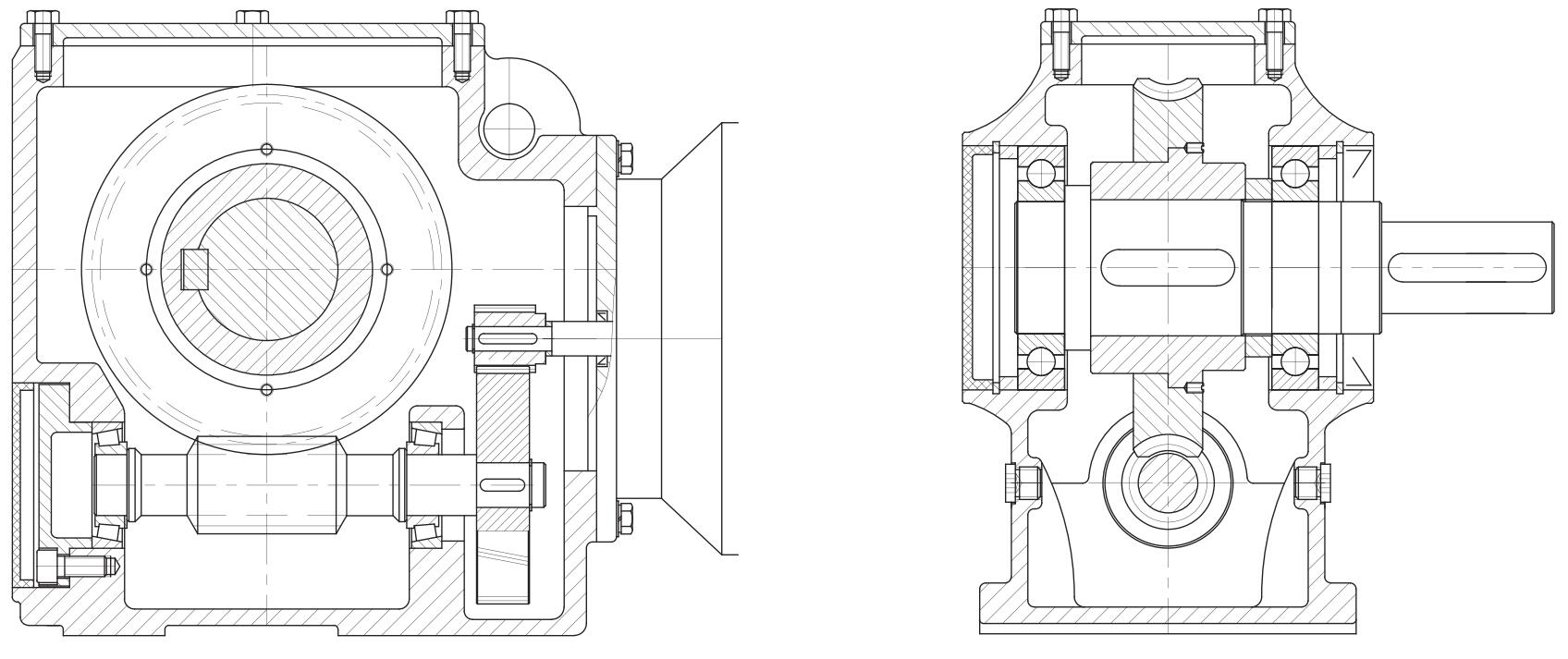

構造図

MODULAR DESIGN

製品写真

応用:

S series worm helical speed reducers are widely used in light industry, food, beer and beverage, chemical industry, escalators, automatic storage equipment, construction, machinery, iron and steel metallurgy, paper-making, wood-based panel machinery, automobile manufacturing, tobacco machinery, water conservancy, printing and packaging, pharmaceutical, textile, building materials, logistics, feed machinery, environmental protection and other fields.