H1HV H2HV H3HV H4HV Hollow Shaft Parallel Shaft Helical Gear Unit

Technical Parameters:

| Available Models | H1HV03~H1HV19, H2HV4~H2HV26, H3HV5~H3HV26, H4HV7~H4HV26 |

| Ratio | 1.25~450 |

| Input power | 5.5~4400 kW |

| Max torque | 2.9~900 kN.m |

DESCRIPTION

H series parallel shaft helical gearbox is designed based on module with parallel shaft. The transmission torque distribution curve is excellent, suitable for heavy load conditions. It adopts advanced grinding technology and shape modification technology, which has high bearing capacity, reliable operation and low noise. The box body is made of high-quality casting to improve the mechanical strength and seismic performance of the reducer. Numerous mounting options are available.

CHARACTERISTICS

- Adopt optimized modular design.

- Parallel shaft output form.

- The transmission torque distribution curve is excellent, suitable for heavy load conditions.

- It adopts advanced grinding technology and shape modification technology, which has high bearing capacity, reliable operation and low noise.

- The box body is made of high-quality casting to improve the mechanical strength and seismic performance of the reducer.

- Numerous mounting options are available.

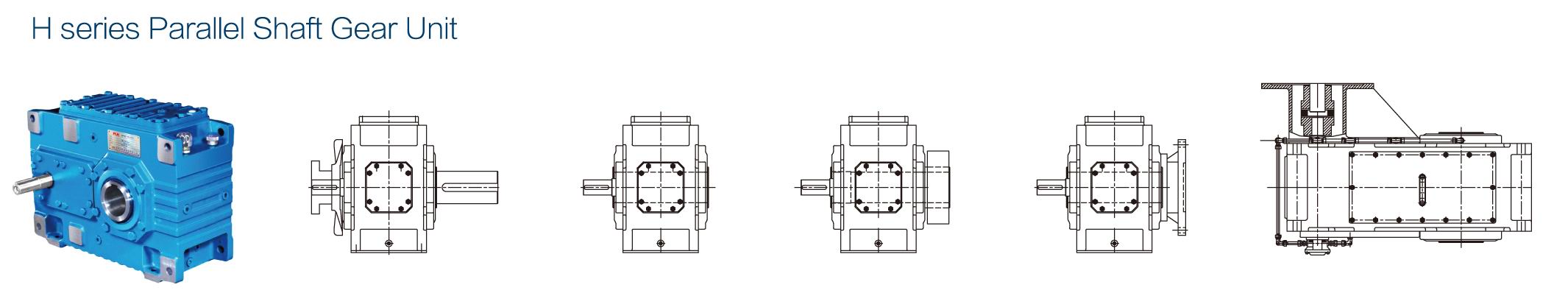

Product Form

- Transmission Stage: single stage, 2 stage, 3 stage, 4 stage.

- Mounting: Horizontal mounted, Vertical mounted

- Parallel Output: Solid shaft, Hollow shaft ( flat key, shrink disk, involute spline), Splined solid shaft, flanged shaft

- Configuration options: With auxiliary tank, with oil pump, with cooling fan, with backstop, with hydraulic coupling, with gear unit swing-base

Technical Data

- Size: H3HV12-50-A, H1HV03~H1HV19, H2HV4~H2HV26, H3HV5~H3HV26, H4HV7~H4HV26

- Technical Data(kN·m): 2.9~900

- Gear Ratio: 1.25~450

- Input Power(kW):5.5~4400

Available Models

| Transmission stage | Ratio(i) | Models |

| H1 | 1.25 – 5.6 | H1HV3, H1HV5, H1HV7, H1HV11, H1HV13, H1HV15, H1HV17, H1HV19 |

| H2 | 6.3 – 28 | H2HV4, H2HV5, H2HV6, H2HV7, H2HV8, H2HV9, H2HV10, H2HV11, H2HV12, H2HV13, H2HV14, H2HV15, H2HV16, H2HV17, H2HV18, H2HV19, H2HV20, H2HV21, H2HV22, H2HV23, H2HV24, H2HV25, H2HV26 |

| H3 | 25 – 112 |

H3HV5, H3HV6, H3HV7, H3HV8, H3HV9, H3HV10, H3HV11, H3HV12, H3HV13, H3HV14, H3HV15, H3HV16, H3HV17, H3HV18, H3HV19, H3HV20, H3HV21, H3HV22, H3HV23, H3HV24, H3HV25, H3HV26 |

| H4 | 90 – 450 | H4HV7, H4HV8, H4HV9, H4HV10, H4HV11, H4HV12, H4HV13, H4HV14, H4HV15, H4HV16, H4HV17, H4HV18, H4HV19, H4HV20, H4HV21, H4HV22, H4HV23, H4HV24, H4HV25, H4HV26 |

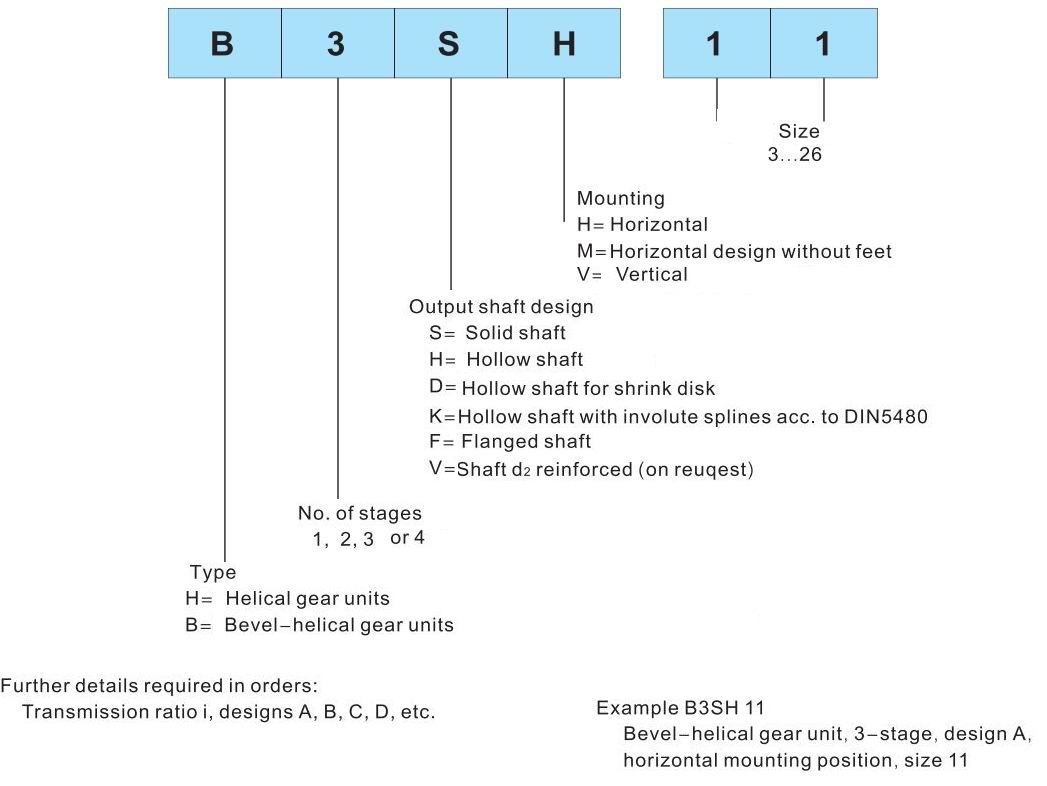

Type and Designation

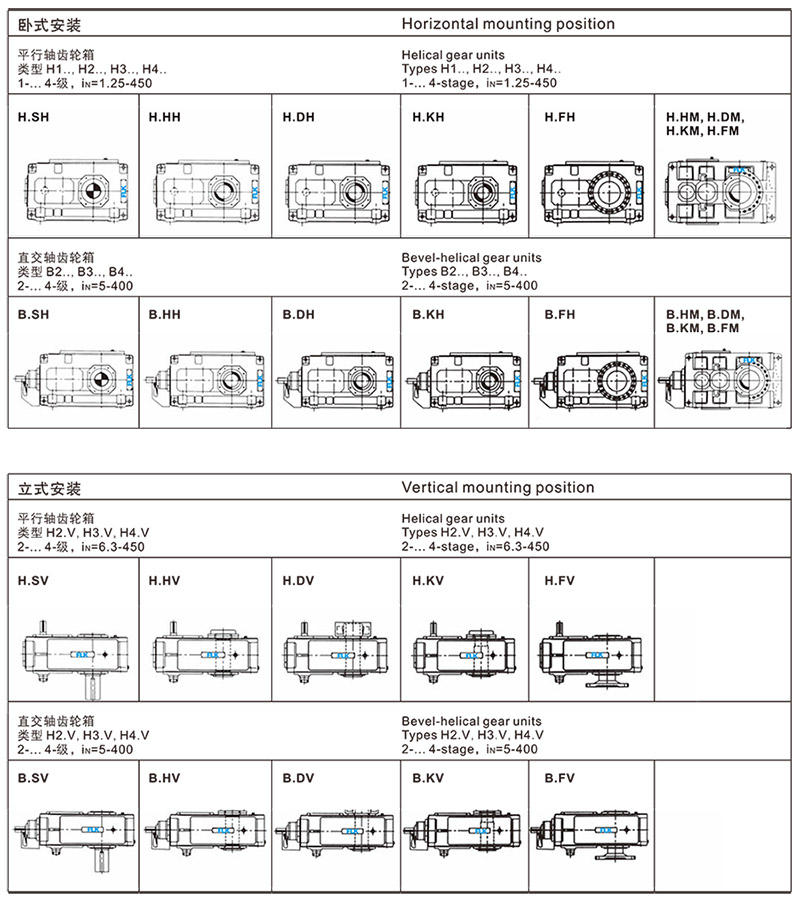

Mounting Position

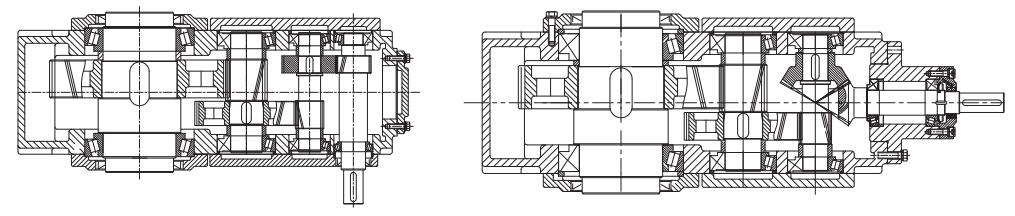

Structure Drawing

MODULAR DESIGN

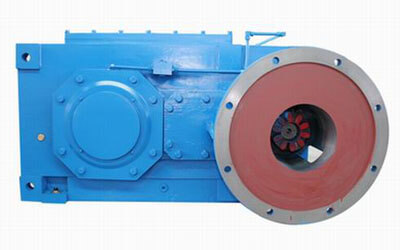

PRODUCT PICTURES

H3HV12 Parallel Shaft Helical Gear Box

H3SH6 Parallel Shaft Helical Gearbox

H3SH12 Helical Reduction Gear Box

Application:

Parallel shaft helical industrial gearboxes are widely used in light industry, food, beer and beverage, chemical industry, escalators, automatic storage equipment, construction, machinery, iron and steel metallurgy, paper-making, wood-based panel machinery, automobile manufacturing, tobacco machinery, water conservancy, printing and packaging, pharmaceutical, textile, building materials, logistics, feed machinery, environmental protection and other fields.