Hシリーズ平行軸ヘリカルギヤボックス

技術パラメータ:

| 利用可能なモデル | H1SH03~H4SH26 |

| 比率 | 1.25~450 |

| 入力電力 | 5.5~4400kW |

| 最大トルク | 2.9~900kN・m |

説明

H シリーズ産業用ヘリカル平行軸ギヤ ユニットは、ヘビーデューティ産業用途向けの高品質ギヤボックスです。すべての機械部品は最先端のソフトウェアで分析され、信頼性が保証されています。また、特定の用途に合わせたソリューションも提供します。

高効率の H シリーズ ヘリカル平行シャフト産業用ギアボックスは、動力伝達市場の中量および重量部門における今日の厳しい用途の要件を満たすために導入されました。平行軸変速機を使用する目的は、減速とトルクの増加です。軸速度1500rpm以下、ギヤドライブ周速度20m/s以下、使用環境温度-40℃~+45℃の高速環境に適しています。ギアボックスはコンパクトで完全に密閉されており、最高精度のポジティブドライブと永続的なアライメントを保証する直接取り付け用に設計されており、スペース要件とレイアウトの問題を最小限に抑えます。 H シリーズ平行軸ヘリカル ギアボックスは、無制限の設置の柔軟性を提供します。

特徴

- 最適化されたモジュラー設計を採用。

- 平行軸出力形式です。

- 伝達トルク配分曲線が優れており、重負荷条件に適しています。

- 高度な研削技術と形状修正技術を採用しており、高い支持力、信頼性の高い動作、低騒音を備えています。

- ボックス本体は高品質鋳物製で、減速機の機械的強度と耐震性が向上しています。

- 多数の取り付けオプションが利用可能です。

製品形態

- 伝送ステージ: シングルステージ、2 ステージ、3 ステージ、4 ステージ。

- 取付方法:横取付、縦取付

- パラレル出力:中実軸、中空軸(フラットキー、シュリンクディスク、インボリュートスプライン)、スプライン中実軸、フランジ軸

- 構成オプション: 補助タンク付き、オイルポンプ付き、冷却ファン付き、バックストップ付き、油圧カップリング付き、ギヤユニットスイングベース付き

技術データ

- サイズ:H1SH03~H4SH26

- テクニカルデータ(kN・m):2.9~900

- ギア比: 1.25~450

- 入力電力(kW):5.5~4400

- ハウジング材質:HT250高強度鋳鉄

- ハウジング硬度:HBS190-240

- ギア材質: 20CrMnTi 合金鋼、その他の要求材質: 17CrNi2Mo、20CrNi4A

- 歯車の表面硬度:HRC58~62

- ギアコア硬度:HRC33~40

- 入出力軸材質:42CrMo合金鋼

- 入出力軸硬度:HRC25~30

- 熱処理:焼き戻し、セメンタイト、焼き入れなど。

- 歯車の加工精度:精密研削、6~5級

- 騒音(MAX):60~68dB

- 潤滑油:GB L-CKC220-460、シェルオマラ220-460

- 温度上昇(MAX):40℃

- 効率: 94%~96% (伝送段による)

- 温度上昇(オイル)(MAX):50℃

- バックラッシュ: ≤20Arcmin

- 振動: ≤20μm

- フレンダーと同じ寸法

利用可能なモデル

| Hシリーズ | 比率 | Bシリーズ | 比率 |

| H1 (1段平行軸ギヤボックス) | 1.25~5.6 | – | – |

| H2 (2段平行軸変速機) | 6.3~28 | B2 (2段ヘリカルベベルギアボックス) | 5~18 |

| H3 (3段平行軸変速機) | 22.4~112 | B3 (3段ヘリカルベベルギアボックス) | 12.5~90 |

| H4 (4段平行軸変速機) | 100~450 | B4 (4段ヘリカルベベルギアボックス) | 80~400 |

| 送信段 | 比率(私) | モデル |

| H1 | 1.25 – 5.6 | H1SH3、H1SH5、H1SH7、H1SH9、H1SH11、H1SH13、H1SH15、H1SH17、H1SH19 |

| H2 | 6.3 – 28 | H2SH4、H2SH5、H2SH6、H2SH7、H2SH8、H2SH9、H2SH10、H2SH11、H2SH12、H2SH13、H2SH14、H2SH15、H2SH16、H2SH17、H2SH18、H2SH19、H2SH20、H2SH21、H2SH22、H2SH23、 H2SH24、H2SH25、H2SH26 |

| H3 | 25 – 112 |

H3SH4、H3SH5、H3SH6、H3SH7、H3SH8、H3SH9、H3SH10、H3SH11、H3SH12、H3SH13、H3SH14、H3SH15、H3SH16、H3SH17、H3SH18、H3SH19、H3SH20、H3SH21、H3SH22、H3SH23、 H3SH24、H3SH25、H3SH26 |

| H4 | 90 – 450 | H4SH5、H4SH6、H4SH7、H4SH8、H4SH9、H4SH10、H4SH11、H4SH12、H4SH13、H4SH14、H4SH15、H4SH16、H4SH17、H4SH18、H34H19、H4SH20、H4SH21、H4SH22、H4SH23、H4SH24、 H4SH25、H4SH26 |

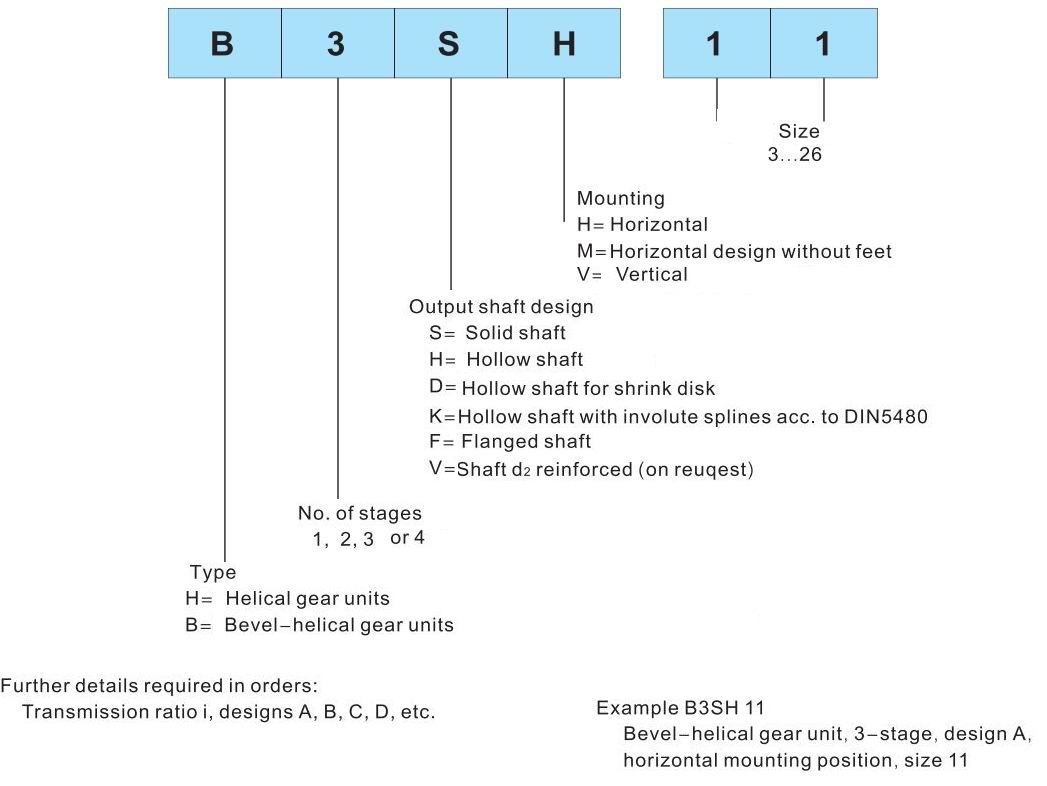

種類と名称

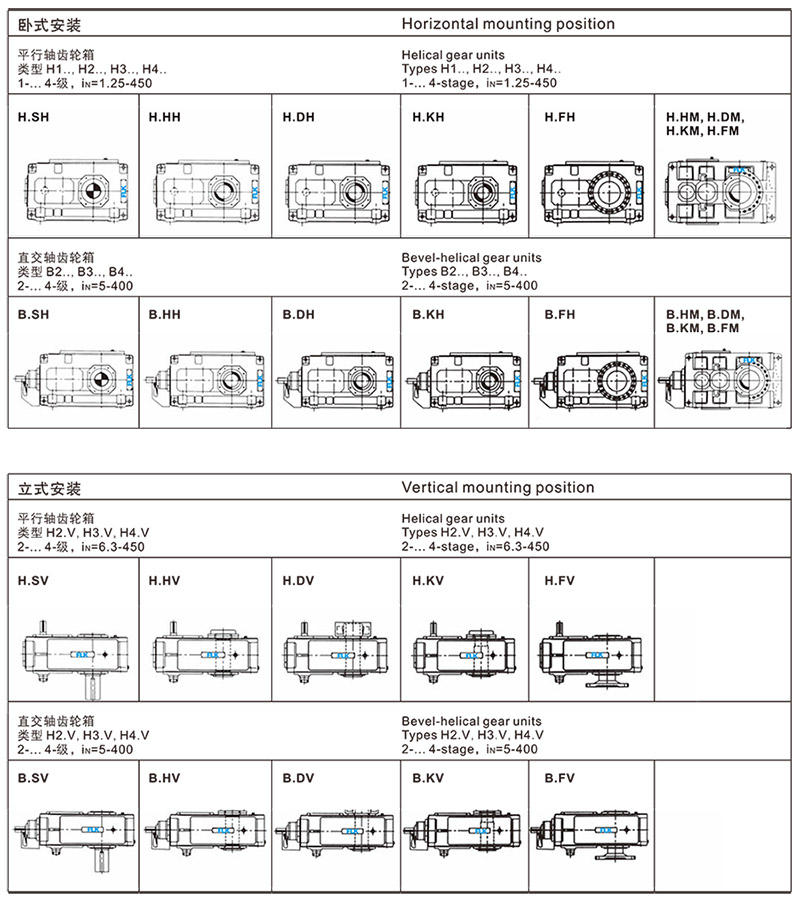

取付位置

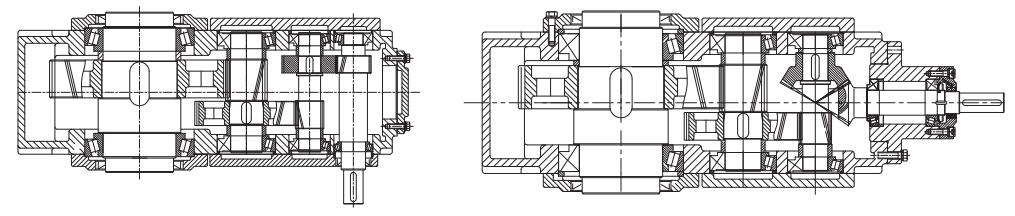

構造図

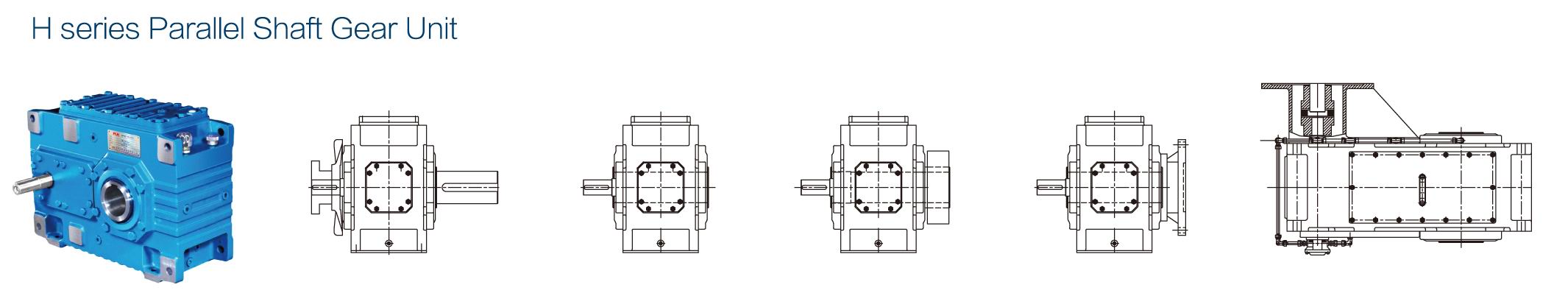

モジュラー設計

製品写真

H3SH5 Parallel Shaft Helical Reduction Gearbox

H3SH6 Parallel Shaft Helical Reduction Gearbox

H3SH12 Helical Reduction GearBox

応用:

H シリーズ平行軸ギアボックスは、軽工業、食品、ビールおよび飲料、化学工業、エスカレーター、自動倉庫装置、建設、機械、鉄鋼冶金、製紙、木質パネル機械、自動車製造、タバコ機械、水利、印刷および包装、製薬、繊維、建材、物流、飼料機械、環境保護などの分野で広く使用されています。