H1HV, H2HV, H3HV, H4HV series Parallel Shaft Helical Gearbox

Paramètres techniques :

| Modèles disponibles | H1HV03~H1HV19, H2HV4~H2HV26, H3HV5~H3HV26, H4HV7~H4HV26 |

| Rapport | 1,25~450 |

| Puissance d'entrée | 5,5 ~ 4 400 kW |

| Couple maximum | 2,9~900 kN.m |

DESCRIPTION

H series parallel shaft helical gearbox is designed based on module with parallel shaft. The transmission torque distribution curve is excellent, suitable for heavy load conditions. It adopts advanced grinding technology and shape modification technology, which has high bearing capacity, reliable operation and low noise. The box body is made of high-quality casting to improve the mechanical strength and seismic performance of the reducer. Numerous mounting options are available.

CARACTÉRISTIQUES

- Adoptez une conception modulaire optimisée.

- Forme de sortie d'arbre parallèle.

- La courbe de répartition du couple de transmission est excellente, adaptée aux conditions de charge lourde.

- Il adopte une technologie de meulage avancée et une technologie de modification de forme, qui présente une capacité portante élevée, un fonctionnement fiable et un faible bruit.

- Le corps de la boîte est fabriqué en fonte de haute qualité pour améliorer la résistance mécanique et les performances sismiques du réducteur.

- De nombreuses options de montage sont disponibles.

Formulaire de produit

- Étape de transmission : étape unique, 2 étapes, 3 étapes, 4 étapes.

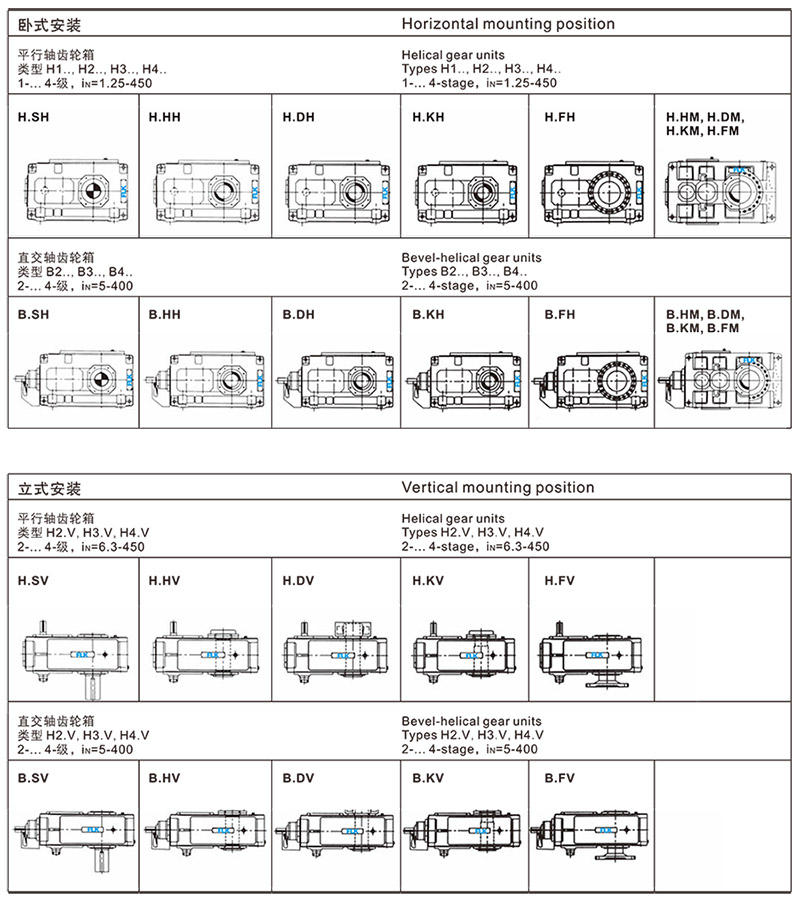

- Montage : monté horizontal, monté verticalement

- Sortie parallèle : arbre plein, arbre creux (clavette plate, frette de serrage, cannelure en développante), arbre plein cannelé, arbre à bride

- Possibilités de configuration : Avec réservoir auxiliaire, avec pompe à huile, avec ventilateur de refroidissement, avec antidévireur, avec accouplement hydraulique, avec réducteur à base pivotante

Données techniques

- Size: H3HV12-50-A, H1HV03~H1HV19, H2HV4~H2HV26, H3HV5~H3HV26, H4HV7~H4HV26

- Données techniques (kN·m) : 2,9 ~ 900

- Rapport de vitesse : 1,25 ~ 450

- Puissance d'entrée (kW) : 5,5 ~ 4400

Modèles disponibles

| Étape de transmission | Rapport(je) | Modèles |

| H1 | 1,25 – 5.6 | H1HV3, H1HV5, H1HV7, H1HV11, H1HV13, H1HV15, H1HV17, H1HV19 |

| H2 | 6.3 – 28 | H2HV4, H2HV5, H2HV6, H2HV7, H2HV8, H2HV9, H2HV10, H2HV11, H2HV12, H2HV13, H2HV14, H2HV15, H2HV16, H2HV17, H2HV18, H2HV19, H2HV20, H2HV21, H2HV22, H2HV23, H2HV24, H2HV25, H2HV26 |

| H3 | 25 – 112 |

H3HV5, H3HV6, H3HV7, H3HV8, H3HV9, H3HV10, H3HV11, H3HV12, H3HV13, H3HV14, H3HV15, H3HV16, H3HV17, H3HV18, H3HV19, H3HV20, H3HV21, H3HV22, H3HV23, H3HV24, H3HV25, H3HV26 |

| H4 | 90 – 450 | H4HV7, H4HV8, H4HV9, H4HV10, H4HV11, H4HV12, H4HV13, H4HV14, H4HV15, H4HV16, H4HV17, H4HV18, H4HV19, H4HV20, H4HV21, H4HV22, H4HV23, H4HV24, H4HV25, H4HV26 |

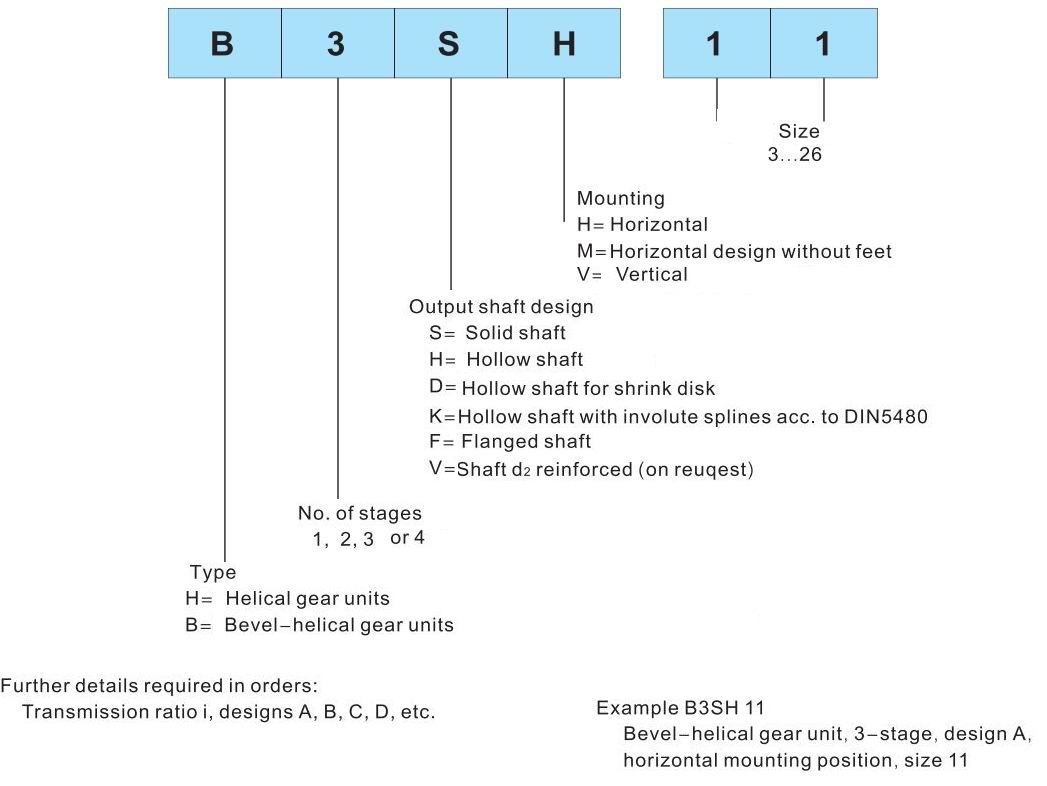

Type et désignation

Position de montage

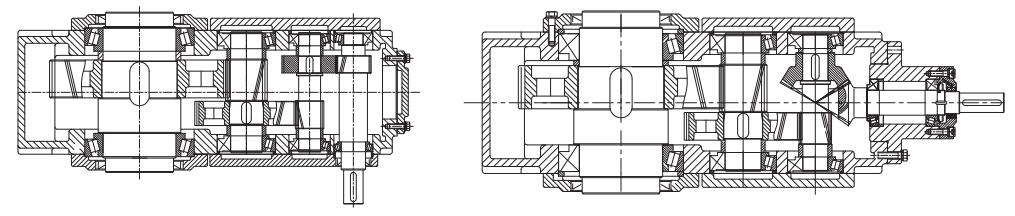

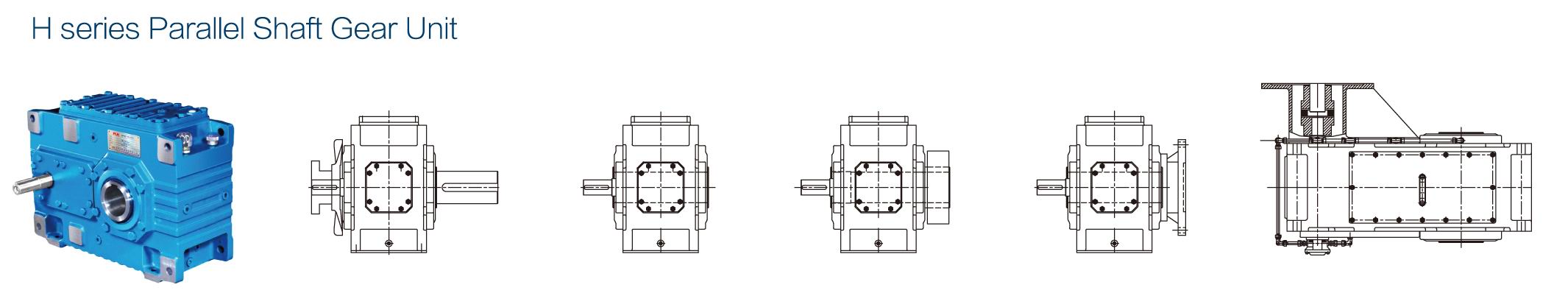

Dessin de structure

CONCEPTION MODULAIRE

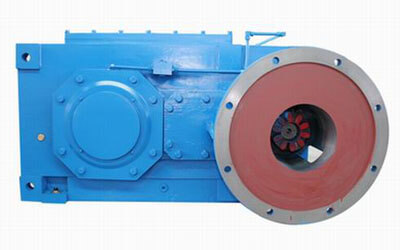

PHOTOS DU PRODUIT

Boîte de vitesses hélicoïdale à arbre parallèle H3HV12

Boîte de vitesses hélicoïdale à arbre parallèle H3SH6

Réducteur hélicoïdal H3SH12

Application:

Parallel shaft helical industrial gearboxes sont largement utilisés dans l'industrie légère, l'alimentation, la bière et les boissons, l'industrie chimique, les escaliers mécaniques, les équipements de stockage automatiques, la construction, les machines, la métallurgie du fer et de l'acier, la fabrication du papier, les machines à panneaux à base de bois, la fabrication automobile, les machines à tabac, la conservation de l'eau, l'impression et l'emballage, les produits pharmaceutiques, textiles, les matériaux de construction, la logistique, les machines alimentaires, la protection de l'environnement et d'autres domaines.