What is a Planetary Gearbox?

Planetary gearboxes (also known as epicyclic gearboxes) are used in various industries because they are compact, durable, and transmit high torque.

A planetary gear box might be a great choice for your business; however, before you make a decision, you should understand which planetary gear box is the right choice based on your needs.

Let’s look at some planetary gear reducer basics, the main planetary gear box types, their pros and cons, their different uses, and how to pick a planetary gearbox.

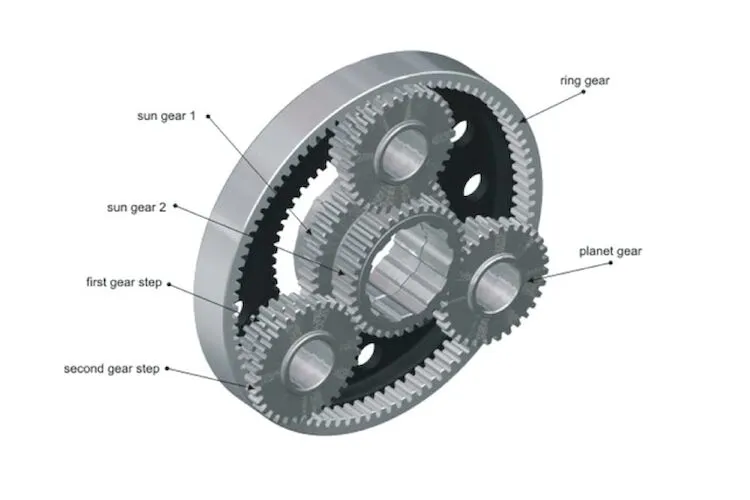

There are three main planetary gearbox components. These are:

- A sun gear (the central component): This gear serves as the driver of the planetary gearbox.

- Several planet gears: These are three or more gears that rotate around the sun gear.

- A ring gear (the outer component): The outer ring gear surrounds the planet gears.

Planetary gearboxes are usually powered by combustion engines or electric motors.

The sun gear transforms the low torque and high-speed loads from the motor into high torque, which is then transferred to the planetary gears. In turn, the planetary gears transfer the load to the outer ring, spindle, or shaft. One of the main benefits of this design is that a high torque planetary speed reducer offers optimal efficiency – almost all of the input energy is transformed into output power.

Why is it Called a Planetary Gearbox?

This gearbox type got its name from its planetary-looking design and the movement of the main components in relation to each other. The sun (solar) gear receives input and triggers the movement of the planet gears, while the ring (satellite) gear has a fixed location in relation to the outer gearbox components.

3 Planetary Gearbox Types

Here are the three main planetary reduction gear box types and their specs:

Shaft Output

With this gearbox, the housing of the gearbox is mounted straight on the machine. The planetary gears are located in a rotating carrier, and the ring is fixed to the carrier, delivering drive to the shaft and resulting in rotating shaft output.

Shaft output gears can deliver up to 113,000 N.m. (Newton-meters) torque.

Spindle Output

This type of planetary gear unit is similar to the shaft output gears. The only difference is that the output is supplied as a flange.

Spindle output gears can deliver up to 113,000 N.m. (Newton-meters) torque.

Wheel Drive

The planet gears in this high torque planetary gearbox type are attached to a wheel carrier and go round the ring gear.

Wheel drive gears can deliver up to 332,000 N.m. (Newton-meters) torque.

Planetary Gearbox Pros and Cons

Before choosing a planetary gear unit, consider these advantages and disadvantages:

Pros

Planetary gearboxes are equally versatile and durable, while requiring low maintenance. They also offer:

- Compact design: This makes planetary gearboxes a great choice for space-constrained operations.

- High efficiency: Only 3% of the initial input is lost.

- High torque density: The planetary parts allow for optimized torque transmission.

- High speed reduction: The planetary gear teeth move all at once, allowing for greater speed reduction than in other gearboxes.

- Lower noise: Planetary gearboxes offer smoother operations with minimal noise levels.

Cons

There are a few disadvantages you should be aware of:

- Higher price: Planetary gearboxes have higher manufacturing costs due to their complex design.

- Overheating: While the compact design is convenient, it may lead to overheating, especially if the gearbox runs for long hours at a time.

- Bearing limitations: The planetary gear box bearings play a vital role in torque transmission and axial force absorption. However, the planetary gearbox has limited space for the bearing installation. While needle bearings are a good fit size-wise, they are not suitable for high axial loads. On the other hand, bearing types that can take on the axial force are too big to be installed on a planetary gearbox.

What are Planetary Gearboxes Used for?

Planetary gearboxes are used in various machines that require light, compact yet powerful gearbox equipment. This includes:

- Conveyors

- Pumps

- Robots

- Printing presses

- Wheel drives

- Steel mills

- Mixers

- Automatic transmissions

- Wind turbines (mostly powered by stronger three-stage wind turbine planetary gearbox units)

How to Choose a Planetary Gearbox Type?

When buying a planetary gear box, take the following factors into consideration:

- Features: This includes torque, casing, backlash, planetary gearbox type, and other vital specs.

- Space: Planetary gearboxes can vary in size, so you need to ensure that the unit will fit perfectly when installed.

- Environment: If the equipment is going to be exposed to dust, dirt, or high humidity levels, try to find a gearbox with good protection.

Are You in Need of Reliable Industrial Planetary Gearbox Services?

Once you have installed your planetary gearbox, it is important to run regular maintenance and service procedures. This will ensure your gearbox is in good health for as long as possible. At FLK Drive, we provide various planetary types. Feel free to reach out to us if you need professional industrial planetary gearbox services. We provide rapid and thoughtful after-sales services for customers all over the world.